X1 technical restauration .. 1 thing to check is the ground connections , these where ok.. cleaned these

the fuel pressure filter and new hoses

zipty to the bracket

bling added.. CF shin spoiler

mnnn .. douse buell part vibrate ? if your not mounting theme correct, they do .. the bushings are rattles out..

cleaned theme ip on the late.. and o-rings used dampening and clamping the cf

nice 🙂

as usualy in Cf some holes need to be drilled.. marking for good hole position

nice

front fender on

using rubber spacers.. so the fender sits away from the front fork ( you see it has been rubbing )

my 9 oclock apointment is there.. service check

looks like clutch cable needs a new one

while the engine is warming up taking of the airbox

and draining the fluids

new belt needs to be mounted too. last one broke

covers and brackets of

has some water in the oil.. short trips ? or clutch cable adjsuter booth ?

clutch cable needs to be replaced, best to remove the shift lever

hanging on a thread

screw the new cable in straight , to keep the crimp connection oil tight

lubing the adjuster or longer lasting fun

oil back in.. and bal and ramp in and adjusted 1/4 turn off after toughting lightly

drop red loctite on the shifter bolt

inspection to the rear, brake pads, need replacement,,

wil loosen the cap en pin , easier when mounted to loosen theme

oil filter of.. stock filter best with the strap tool

new filter on

removing the foot peg plate

wheel bearing check .. meeehhh cannot turn these by hand , when in dought.. replace them

new ones.. pressed in correctly.. smooth turnings

new belt on and swing arm brace mounted before you tighten the rear axle

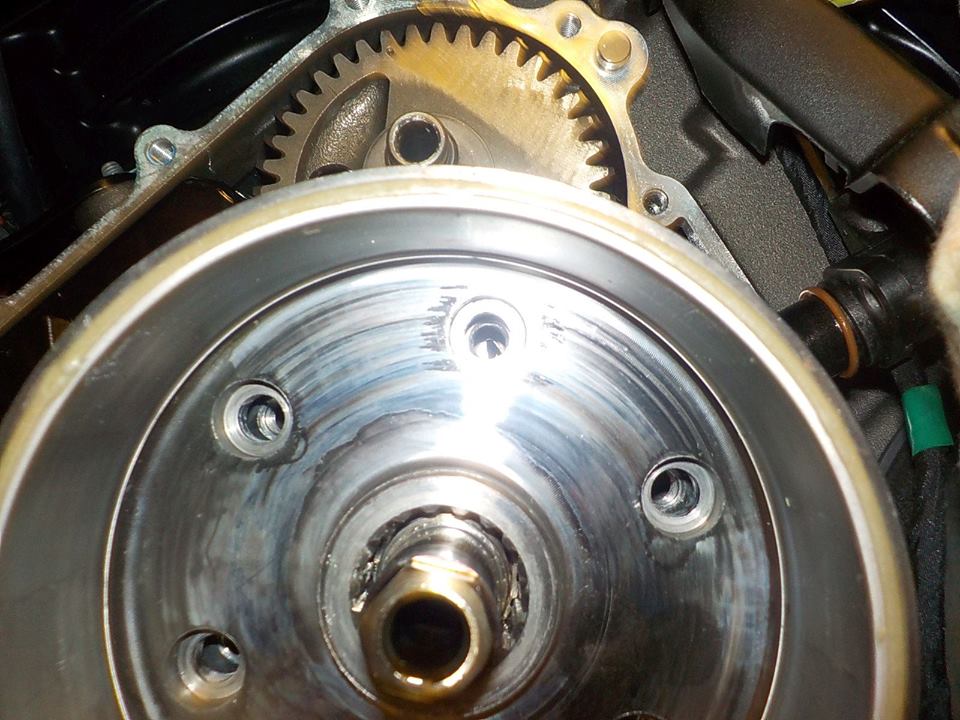

checking primairy chain tension

new pads in and caliper back on

chin spoiler bracket on

clutch cable needs to route trough the top triple plate

wrong plugs ? look like it

yep… not sure why HD work shops still put 6r12 plugs in XB.. been a while that even Sportsters use these plugs.. these are not good for buell

front spark plug cable has a little corrosion in the plug wire

rear plug with extention and wobble joint

bike truned around.. front end check

wheel bearings feel bad..

replaced the front bearings

cleaning the front brake.. was a digital one.. ( on/off ) old grease makes it like this

new brake fuild..looks like this has been in a long time, as the fluid has been sweating through the rubber

fresh fluid in

pushing down the front end to set the front forks on the axle , oil level check.. and she can go back to Belgium

on with the X1.. custom one piece cover.. need to turn the fuel vent in

pain in the but to mount it .. but a the one piece cover is nice

and for the first time in 5 years.. she runs on here one.. little trouble still starting.. but let here warm up a little

clutch cable was still leaking a little, so longer piece of heat shrink with glue mounted

bike only want to start when i pull the clutch, other wise the start motor turns over but no spark.. neutral switch ?

checking.. not really bad, 2 Ohm

and now not at all working ?

some bad diodes are not playing nice.. i will spray some contact cleaner in the box and let it sit for a while ..

while i put new brake fluid in the front brake.. chewy screws .. will replace theme

black brake fluid ? that is new to me 😉

some fresh fluids in and bleed bought calipers

new screws in.. rest of the cosmectic will come at a later stage

horn not working.. switch

opening up.. after long time the contacts get corroded..

it has power.. so indeed the switch is bad

not for the people who get nervois from little things.. clean op the contacts and the spring , did the trick

to morrow test ride  🙂 first time in many years this bike is back on the road

🙂 first time in many years this bike is back on the road

https://www.twinmotorcycles.nl/artikelen.asp?cid=20&aid=1237

😉

😉

🙂

🙂

.jpg)

🙂 — bij

🙂 — bij