What did we do today 12-1-2018 Buell XB120X exhaust retainer clips broken, Buell S1 fork seals

Uly time — at Twin Motorcycles Buell Support forever.

.jpg)

somthing fishy at the front header pipe — at Twin Motorcycles Buell Support forever.

and neutral switch is broken — at Twin Motorcycles Buell Support forever.

we need to rotate the engine down to fix this so airbox off — at Twin Motorcycles Buell Support forever.

top tie rod loose — at Twin Motorcycles Buell Support forever.

O2 sensor connector loose , as we need to take the headers of — at Twin Motorcycles Buell Support forever.

moving from up to down… scoops loose — at Twin Motorcycles Buell Support forever.

the temp fix removed — at Twin Motorcycles Buell Support forever.

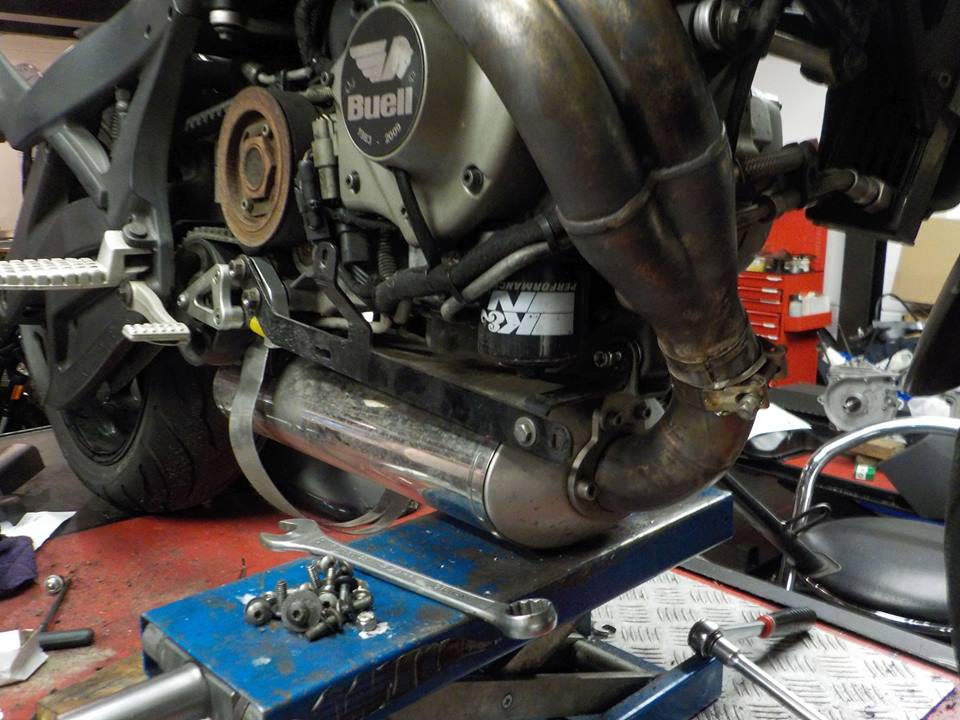

exhaust needs to come of — at Twin Motorcycles Buell Support forever.

and loosening the rear straps — at Twin Motorcycles Buell Support forever.

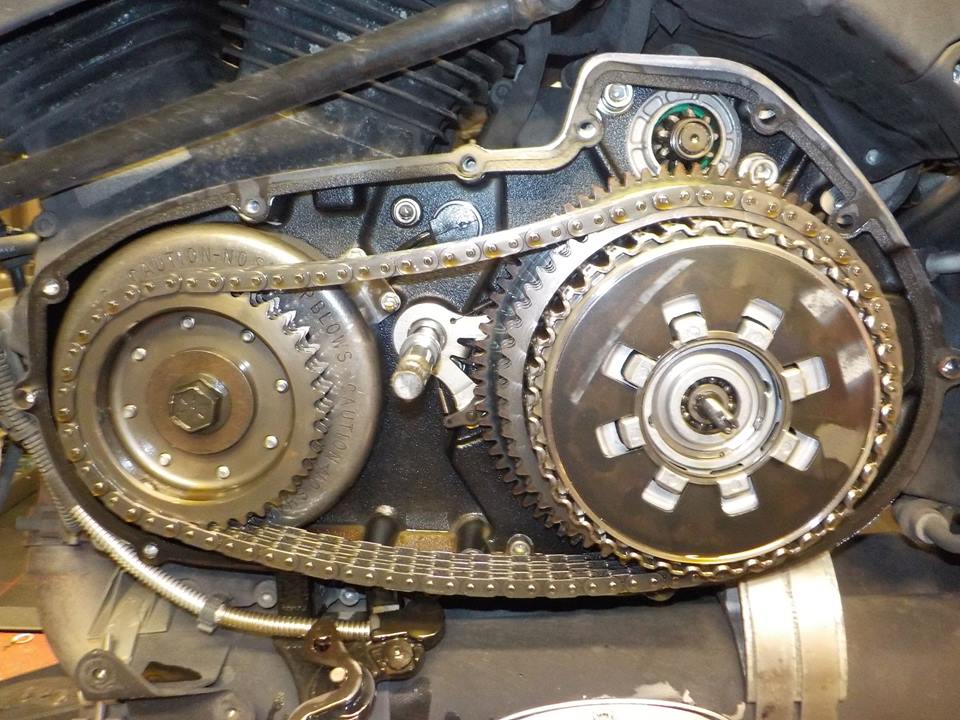

pully cover of , we also need to check the belt tensioner — at Twin Motorcycles Buell Support forever.

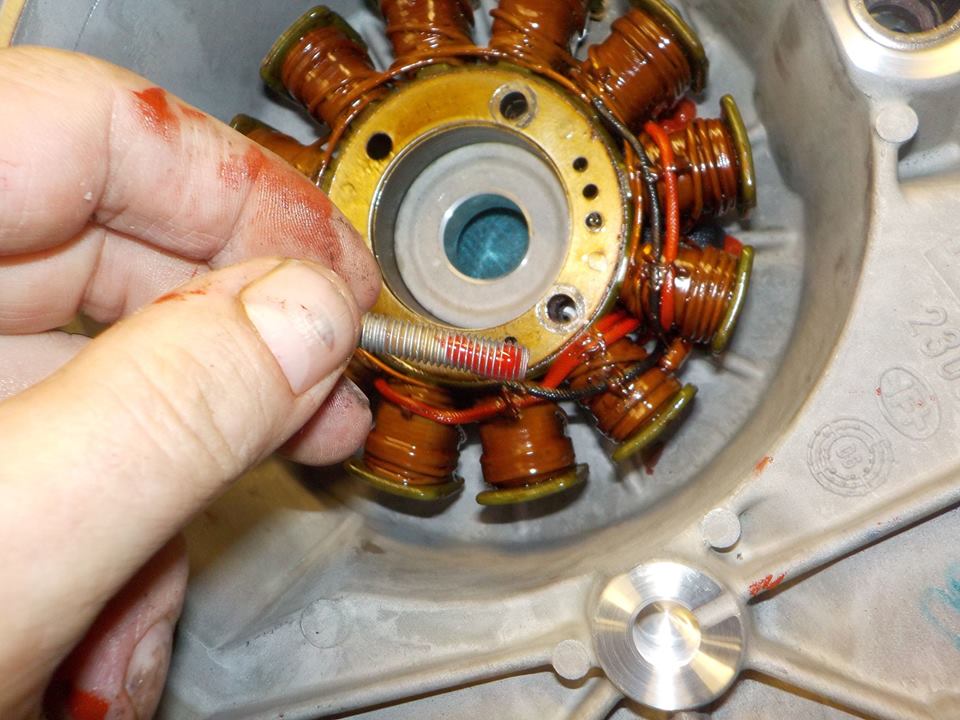

spring is corroded , i will clean and lube it and put a new spring on — at Twin Motorcycles Buell Support forever.

unlucky… normaly first carefully try to tighten a little before losening… no way . this one broke — at Twin Motorcycles Buell Support forever.

the other one did work..lots of loose , tighten with penitrating oil , will replace the nuts anyway — atTwin Motorcycles Buell Support forever.

engine rotated down to loosen the rear bolts and take the header of — at Twin Motorcycles Buell Support forever.

the retaining ring is gone , corroded and fell out i think .. that is the only thing that keeps the headers to the heads — at Twin Motorcycles Buell Support forever.

header has been rattleing inside the flange — at Twin Motorcycles Buell Support forever.

clutch cable bracket out the way to drill the stud out .. will replace this screw. this one is for the trash can— bij Twin Motorcycles Buell Support forever.

my trusted drill plate… has seen many broken studs— bij Twin Motorcycles Buell Support forever.

and still works.. secret is also to use a cobalt or carbide drill bit.. dril care full as if you break a carbide dril bit .. need to be to the edm shop to get it out ( head removal ) — bij Twin Motorcycles Buell Support forever.

hole drilled , now retap it — bij Twin Motorcycles Buell Support forever.

check… — bij Twin Motorcycles Buell Support forever.

check… — bij Twin Motorcycles Buell Support forever.

.jpg)

new nuts on the stud , i use loctite to mount the studs.. and screw the stud in same lenght as the other one

replacing the rear retaining rings to

you see , also not the best anymore

header on , new nuts

looking good , time to rotate the engine up again

front bolt to 66 NM

loosening the rearr axle and belt of

belt of the front pully

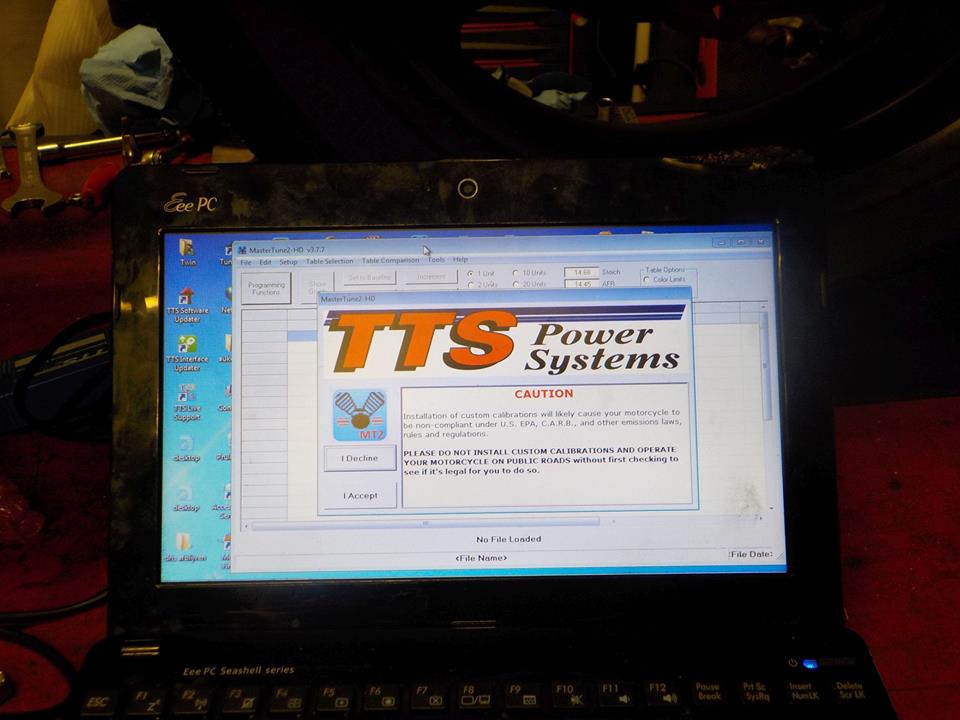

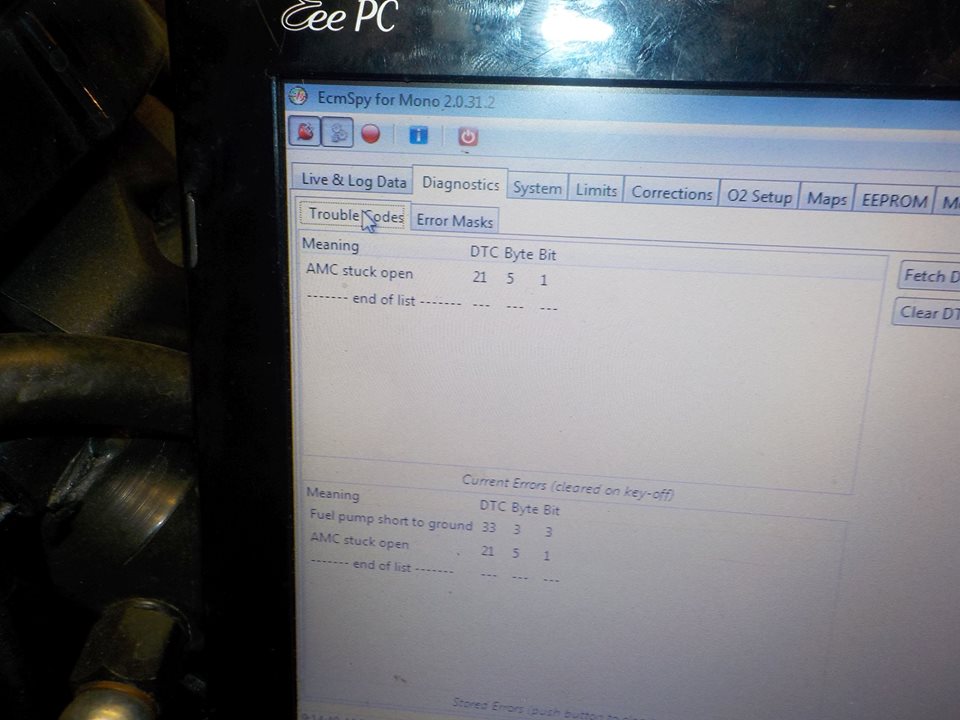

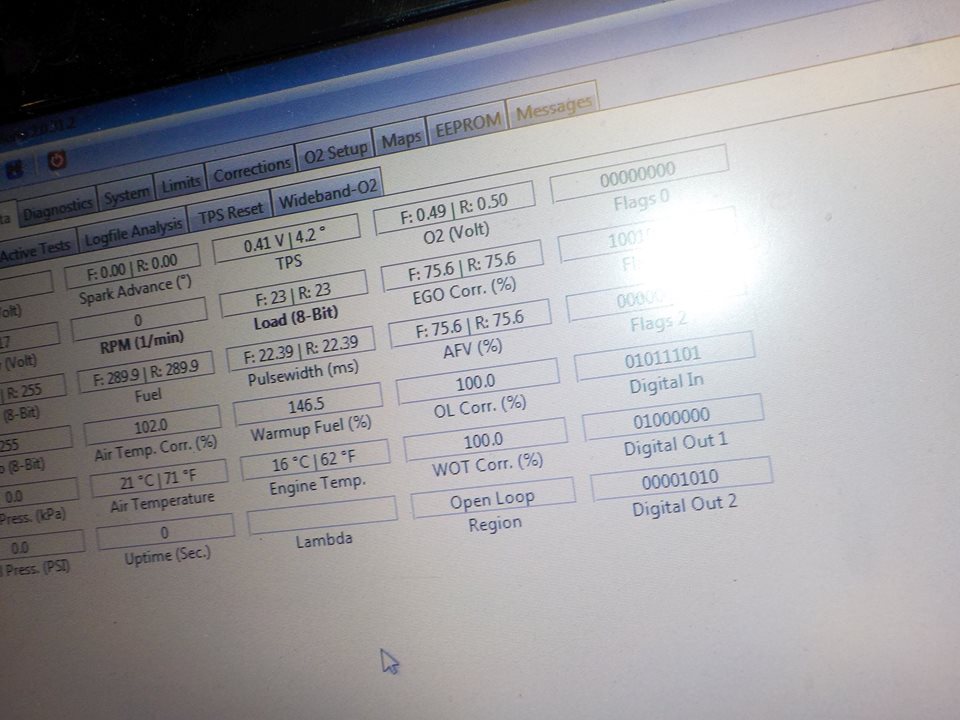

and double check on the neutral sensor.. yes to much resitance ( very common problem )

so old one out

new one in and testing …

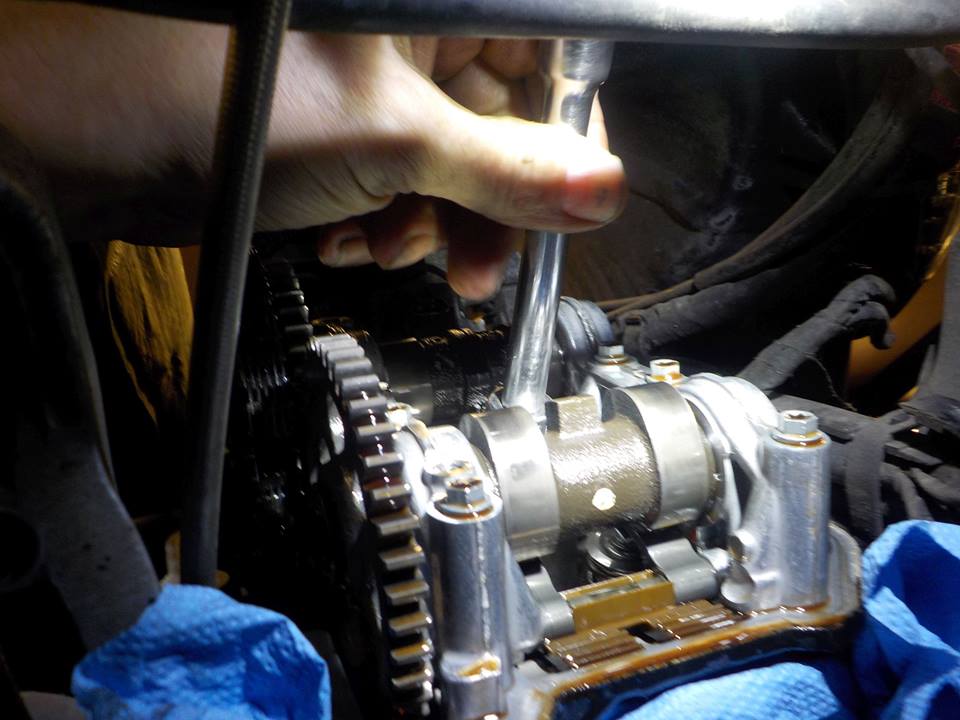

taking apart the tensioner

little cleaning can not hurt

pivot has some markings

cleaned and lubed

assembly

and tighten the pivot with the counter sunk screw

spacer the idler out

and mounting the rest.. TQ hammer exhaust back on

ziping the breather hose so it will not tought the header

scoops back on

and moutning the top tie rod

little battery.. much room for ecm to put next to it .. so the seat douse no longer rest on it

.jpg)

and checking the work… running nice again.. no exhaust fart or rattle

Nice S1 front fork has sprong a leak

right side was done already

left side is leaking now

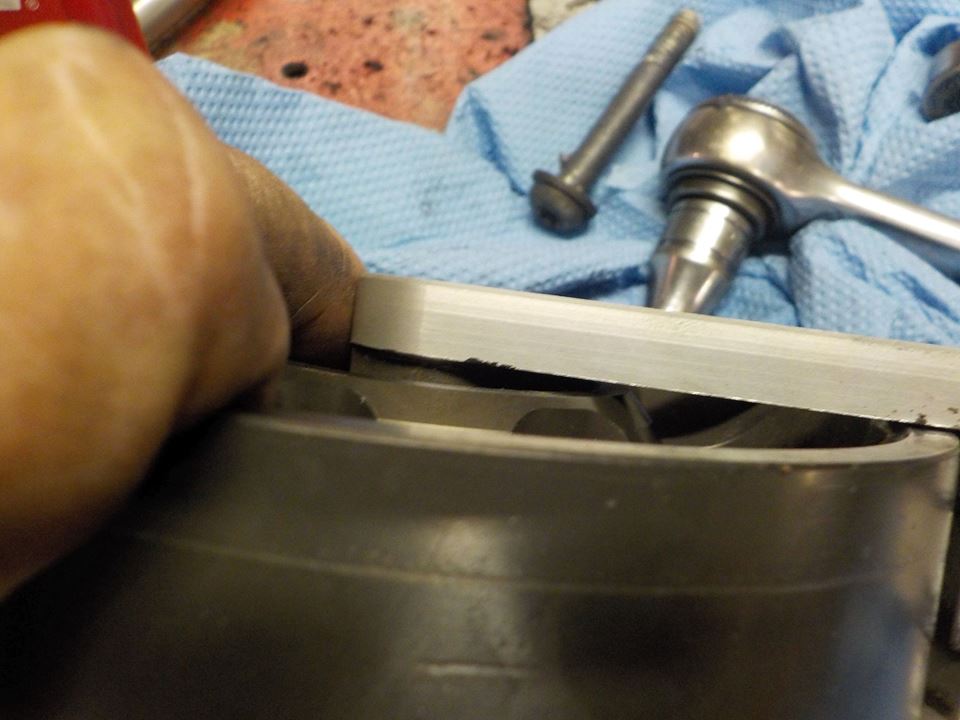

so axle loose and fork taken out .. protect the top cap nut

pull the top cap of, to get to the locking rings

taking apart is easy , note the spring preload rings

oil seal is hold in with a retainer ring and seating ring.. bought will corrode over the years.. best to replace these

wp fork inners

new seal on…. protect the sharp edges

bushings and spacer rings back on

seal knocked in and new retainers mounted

filled with oil and bleeded the demper ( left side is rebound only, right side is compression only ) and mounting the lock rings

.jpg)

fork in.. axle in.. drop of blue loctite and tighten the front nut

mounting the front fender screws.. use a light loctite

https://www.twinmotorcycles.nl/artikelen.asp?cid=20&aid=2259

.jpg)

.jpg) engine rotated up .. engine bolt in , not tight yet

engine rotated up .. engine bolt in , not tight yet

.jpg)

.jpg)

front O2 back in

front O2 back in

she is running sweet.. and still looking good with 60000 km done now…

she is running sweet.. and still looking good with 60000 km done now…  🙂

🙂

.jpg)

.jpg)

😉

😉

.jpg)

and remove

and remove

.jpg)

pulling out the strainer and cleaning it

pulling out the strainer and cleaning it

.jpg)

.jpg)

.jpg)

a little light so i can see what i’m doing

a little light so i can see what i’m doing

.jpg)

not bad. but still customer will notice there are new ones in

not bad. but still customer will notice there are new ones in

checking the cap on these to

checking the cap on these to

.jpg)

.jpg)

.jpg)

.jpg)

new one sin

new one sin

.jpg)

.jpg) just checking with some fimo the ecm clears the seat now

just checking with some fimo the ecm clears the seat now

.jpg)

speed sensor same place as all but on the 2008 -up more difficult to get to

speed sensor same place as all but on the 2008 -up more difficult to get to

.jpg)

.jpg) hope this fixes it , other wise the sensor needs replacement

hope this fixes it , other wise the sensor needs replacement

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

sprag bearing back in the holder ( outer race )

sprag bearing back in the holder ( outer race )

.jpg)

.jpg)

.jpg)

🙂

🙂