Monthly Archives: December 2018

6-6-2018, Buell XB12X 08 last things for startup, Buell S3 oil filler cap popping out , Buell X1 technical restauration

Powercommander out.. very glad good connection where made.. was easy to remove — at Twin Motorcycles Buell Support forever.

but i will do a favour and reposition the ecm as i see the markings on the connectors.. ULY problem. adn will fuck up the ecm , breaking the ecm board — atTwin Motorcycles Buell Support forever.

original mount bended and mount here , ziptie it — at Twin Motorcycles Buell Support forever.

oil meter.. with oil feed — at Twin Motorcycles Buell Support forever.

so mounting back the oil line to the meter — at Twin Motorcycles Buell Support forever.

oil filter on — at Twin Motorcycles Buell Support forever.

now first make the oil pressure normal again

as a plain bearing crank was made .. and this leaded to a cascade off problem.. so the oil pressure and feed line diameter where made bigger

this caused the crank to turn 3/4 in oil .. loosiing 8 Hp , as the plain bearings had to much side play… anyway…. now with roller bearing crank back in.. good the oil pressure can be go back to normal

break in oil used for the first 50 km — at Twin Motorcycles Buell Support forever.

shifter on — at Twin Motorcycles Buell Support forever.

checking the primairy chain tension — at Twin Motorcycles Buell Support forever.

sparkplugs out — at Twin Motorcycles Buell Support forever.

coil connector loose — at Twin Motorcycles Buell Support forever.

and fuel pump loose, to turn the engine over for oil pressure — at Twin Motorcycles Buell Support forever.

normaly you will have a very hard time to turn the engine on the startermotor and get oil pressure , this will take to long.. with a little airpressure in the swingarm.. you can get much quicker oil pressure ( light out ) — at Twin Motorcycles Buell Support forever.

plugs in and start up… 10 seconds the first cycle — at Twin Motorcycles Buell Support forever.

S3 in need off some attention.. the oil filler plug is popping of because the pressure in the oil tank.. with stock oil pump.. a sign the rings are gone ( to much case pressure / blow by ) — at Twin Motorcycles Buell Support forever.

plug with napkin — at Twin Motorcycles Buell Support forever.

oil level is ok , not to much .. half on the stick , is not blocking the breather hose — at Twin Motorcycles Buell Support forever.

spark plugs out.. mnnn nice and white.. running way to lean — at Twin Motorcycles Buell Support forever.

checking compression — at Twin Motorcycles Buell Support forever.

will ok.. still looks good — at Twin Motorcycles Buell Support forever.

front the same — at Twin Motorcycles Buell Support forever.

looking at this .. i think strip down is the best option ,— at Twin Motorcycles Buell Support forever.

intake off — at Twin Motorcycles Buell Support forever.

breather bolts out — at Twin Motorcycles Buell Support forever.

front one is easy the rear one cannot be turned , — at Twin Motorcycles Buell Support forever.

mnn.. not sure i like the no front mount exhaust , the header feels loose , but is not, so has play on the gaskets — at Twin Motorcycles Buell Support forever.

the headerbolt… am i lucky  🙂 — at Twin Motorcycles Buell Support forever.

🙂 — at Twin Motorcycles Buell Support forever.

tighten and loose with some wd40 — at Twin Motorcycles Buell Support forever.

1 out — at Twin Motorcycles Buell Support forever.

2 out — at Twin Motorcycles Buell Support forever.

2 out with studs and 2 nuts.. yep i’m lucky to day  :-)— at Twin Motorcycles Buell Support forever.

:-)— at Twin Motorcycles Buell Support forever.

running hot ? fuel line is crackeling — at Twin Motorcycles Buell Support forever.

choke cable loose — at Twin Motorcycles Buell Support forever.

if some one wonders about the bagstar tank cover ?— at Twin Motorcycles Buell Support forever.

fuel tank of — at Twin Motorcycles Buell Support forever.

intake manifold is loose ? i can turn it — at Twin Motorcycles Buell Support forever.

carb of — at Twin Motorcycles Buell Support forever.

and starting to take the top mount off — at Twin Motorcycles Buell Support forever.

tail section of to make room — at Twin Motorcycles Buell Support forever.

more room — at Twin Motorcycles Buell Support forever.

rear rocker cover screws.. under the frame is a special tool for it  🙂 — at Twin Motorcycles Buell Support forever.

🙂 — at Twin Motorcycles Buell Support forever.

cover of and loosening the lower box — at Twin Motorcycles Buell Support forever.

under the frame with a spanner — at Twin Motorcycles Buell Support forever.

mnn way to loose to be good — at Twin Motorcycles Buell Support forever.

le cut off 1/4 allen key to loosen the screws , with the ball end you can turn theme out — at Twin Motorcycles Buell Support forever.

omg.. these are the wurst i ever seen .. this could not be a nice ride .. no way — at Twin Motorcycles Buell Support forever.

head of.. breaker bar make short work with suborn head bolts — at Twin Motorcycles Buell Support forever.

protecting the lifter holes from debris — at Twin Motorcycles Buell Support forever.

cylinder of , yes i see where it is blowing , you can feel the markings with your nail — at Twin Motorcycles Buell Support forever.

the 2e compression ring is completely shining… as a sign these are worn out — at Twin Motorcycles Buell Support forever.

ok front .. — at Twin Motorcycles Buell Support forever.

to make some more room.. lift teh engine — at Twin Motorcycles Buell Support forever.

and remove the front engine mount — at Twin Motorcycles Buell Support forever.

this one has been replaced — at Twin Motorcycles Buell Support forever.

this one not… i will clean this and put some neverseas on the shank — at Twin Motorcycles Buell Support forever.

front mount of ( old style 1/2 bolt ) — at Twin Motorcycles Buell Support forever.

will do the throttle cable to…. — at Twin Motorcycles Buell Support forever.

front bolts out — at Twin Motorcycles Buell Support forever.

front cylinder is a little better.. but also ready for replacement — at Twin Motorcycles Buell Support forever.

rule of thumb.. when to bore/ hoine oversize when to replace.. if you can feel the liner with your finger nail… replace the cylinders.. change after OS honing the lyner comes loose , waste off money — at Twin Motorcycles Buell Support forever.

front rings look better , but piston is spend — at Twin Motorcycles Buell Support forever.

for now hang the engine it a strap to discus repair with the customer — at Twin Motorcycles Buell Support forever.

test ride with the X1 restauration project.. nice ride  🙂 but speedo douse not work — at Twin Motorcycles Buell Support forever.

🙂 but speedo douse not work — at Twin Motorcycles Buell Support forever.

speedo sensor can be reached with a little fiddling — at Twin Motorcycles Buell Support forever.

no metal on the sensor — at Twin Motorcycles Buell Support forever.

locating the speedo sensor connector ( older models is under the battery ) — at Twin Motorcycles Buell Support forever.

normaly you can measure nothing between white and red — at Twin Motorcycles Buell Support forever.

wheel in the air to check — at Twin Motorcycles Buell Support forever.

mnnn dous not work — at Twin Motorcycles Buell Support forever.

checking the connector in the ecm — at Twin Motorcycles Buell Support forever.

hehe.. starting to have some good signal — at Twin Motorcycles Buell Support forever.

sorry moved to much.. but speedo is working — atTwin Motorcycles Buell Support forever.

What did we do today: 2-6-2018, Buell XB12X engine mount finish, Buell XB12SX inspection , Buell 1125CR belt

dowls in the locating holes — at Twin Motorcycles Buell Support forever.

new gasket and tq the cover starting in the middle spiral out — at Twin Motorcycles Buell Support forever.

oil drain plug check.. if tight and good

clutch cable in

oil back in the gear box

the exhaust bearings back in the case

and w-brace on for now

new o-ring on the crank sensor..

sensor and plate on

the later uly side stand had 3 mounting holes.. learned from the olders ones 2 bolts is cutting it close with sutch a long stand

red loctite and tighten theme like you mean it

we will route the wires nicely later on for now connectors on will do

clutch cable on

check over XB12SX..

they exist.. only 2400 km done .. note the neutral light is out — at Twin Motorcycles Buell Support forever.

so check up is easy. bolts and nuts, was kept dry and warm.. neutral switch needs replacement, cover off

rear caliper of

and axle and out

to get the belt off

checking the sensor.. way to much resistance

5/8 ( 16 mm ) high thin socket.. and you can replace it

easy check.. new switch.. works

so all back on

with some loctite on the chin spoiler screws

checking primairy chain tension.. normaly this needs to be checked with warrenty check.. but this bike just has a oil service done.. i bet you they did not look at the chain.. as it was a little to tight

headlight out.,,

screen off and headlight out

pull the connector off the bulb

than place the bulb by losening the spring clip

light bulb out with so little km.. checking teh voltage when running.. is ok on the high side but ok — atTwin Motorcycles Buell Support forever.

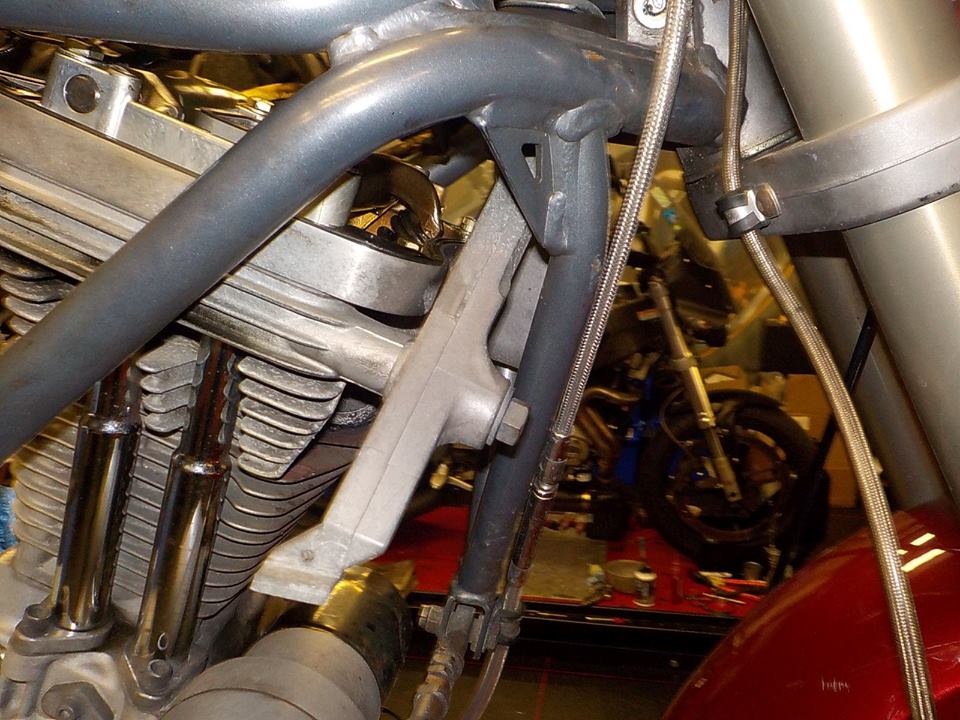

on with the Uly.. exhaust brace on — at Twin Motorcycles Buell Support forever.

and very tick oil feed line ( this was made bigger to get enough oil in the crank with the plain bearing modification ) — at Twin Motorcycles Buell Support forever.

it will do.. not nice , but no pressure on this .. and we make the oil pressure normal again, so the case is not filled with oil completely ( one off the problems on this bike ) — at Twin Motorcycles Buell Support forever.

engine down again — at Twin Motorcycles Buell Support forever.

just enough to mount the headers — at Twin Motorcycles Buell Support forever.

a set off test headers is mounted, as the bike needs to be adjusted on the dyno — at Twin Motorcycles Buell Support forever.

last change to put the pcv valves in — at Twin Motorcycles Buell Support forever.

engine up and exhaust can go on — at Twin Motorcycles Buell Support forever.

truck hardware used — at Twin Motorcycles Buell Support forever.

you know your belt is getting old when you can mount the idler with out loosening the wheel axle  ;-)— at Twin Motorcycles Buell Support forever.

;-)— at Twin Motorcycles Buell Support forever.

breather hose made connected up — at Twin Motorcycles Buell Support forever.

pully on and lock plate mounted — at Twin Motorcycles Buell Support forever.

and connected — at Twin Motorcycles Buell Support forever.

the bike came with these.. — at Twin Motorcycles Buell Support forever.

the bike came with these.. — at Twin Motorcycles Buell Support forever.

now i have seen these before, so some one is selling these as fitting for Xb — at Twin Motorcycles Buell Support forever.

yes they fit.. but you will not stay happy long.. as these cables are way to long — at Twin Motorcycles Buell Support forever.

and will start rubbing everyware — at Twin Motorcycles Buell Support forever.

so.. — at Twin Motorcycles Buell Support forever.

take some OEM ones.. they are not really expencive , but good value for money — at Twin Motorcycles Buell Support forever.

1125cr belt change.. quicky — at Twin Motorcycles Buell Support forever.

guards of — at Twin Motorcycles Buell Support forever.

pich bolt loose — at Twin Motorcycles Buell Support forever.

axle about 15 turns out so the bearing sits on the thinner section of the axle — at Twin Motorcycles Buell Support forever.+

swingarm piece out — at Twin Motorcycles Buell Support forever.

left peg.. top and front bolt loose , and loosent he idler bolt , now you can twist the brace and puth the belt through — at Twin Motorcycles Buell Support forever.

it is time .. — at Twin Motorcycles Buell Support forever.

new belt on — at Twin Motorcycles Buell Support forever.

footpeg back on — at Twin Motorcycles Buell Support forever.

swing arm piece on and turn the wheel , to slide the belt on — at Twin Motorcycles Buell Support forever.3

set to tq .. please note we checked the wheel bearings from this bike 2 weeks ago.. other wise i would have checked these now.. as the belt tension is big on these new belts, the bearings need to be in top shape, — at Twin Motorcycles Buell Support forever.

1-6-2018 Xb12X engine, prep for fuel pump replacement, XB service and check up , mounting XB12X engine

mounting head gaskets.. put a drop off oil on the flats and threads so they will reach the correct force— at Twin Motorcycles Buell Support forever.

3 step methode

and finish with 90 deg. .. nice to have a good tq wrench  🙂

🙂

mounting the push rods

identifications markings are gone

no problem they are in lenght differance , long ones are exhaust

scaring on the rocker box bolts shanks

this is caused by the rocker shaft lock , make sure these line out.

and keep the rocker box level when you tighten

and tighten the bolts

some squirt of oil to help start up lube

top engine mount on

coil bracket on line out the hole

vacuum port is cracked — at Twin Motorcycles Buell Support forever.

new one mounted — at Twin Motorcycles Buell Support forever.

manifold on — at Twin Motorcycles Buell Support forever.

starter motor on — at Twin Motorcycles Buell Support forever.

08 up engines route the stator wire to the front — at Twin Motorcycles Buell Support forever.

ready to be mounted — at Twin Motorcycles Buell Support forever.

2010 XB9SX… fuel pressure ossilating.. we are going to replace the complete fuel pump.. it is comming in to day.. so prep as far as i can — at Twin Motorcycles Buell Support forever.

airbox covers of — at Twin Motorcycles Buell Support forever.

drain line to the fuel line — at Twin Motorcycles Buell Support forever.

and with testing fuel pump , a clean way to drain the tank — at Twin Motorcycles Buell Support forever.

left foot peg of — at Twin Motorcycles Buell Support forever.

the culprit… the wire connection trough the base .. causes this ossilating fuel pressure problem, as on the 2010 XB and 1125 models the fuel pressure is regulated with voltage differance in the ecm — at Twin Motorcycles Buell Support forever.

swing arm axle loose — at Twin Motorcycles Buell Support forever.

and wheel axle loose — at Twin Motorcycles Buell Support forever.

rear shock bolt loose — at Twin Motorcycles Buell Support forever.

my 10 oclock apointment has arrived XB12 something ( vin is a XB12R ) but has a SS tail and S front — at Twin Motorcycles Buell Support forever.

very nice wrapping on the frame — at Twin Motorcycles Buell Support forever.

SS tail cobbled on — at Twin Motorcycles Buell Support forever.

will put some zipties here — at Twin Motorcycles Buell Support forever.

draining the oil .. little debirs on the drain plug.. a little bit normal for these older engines..but keep a eye out for this.. — at Twin Motorcycles Buell Support forever.

rear wheel check .. caliper off — at Twin Motorcycles Buell Support forever.

no.lazy mechanics. i will rotate this up — at Twin Motorcycles Buell Support forever.

the familiar bad fitting on the right side airscoop — at Twin Motorcycles Buell Support forever.

clutch cable needs some attention as it is now burning to the header — at Twin Motorcycles Buell Support forever.

easy fix with a nice bracket — at Twin Motorcycles Buell Support forever.

gearbox oil in — at Twin Motorcycles Buell Support forever.

just checking.. old style side stand bolt — at Twin Motorcycles Buell Support forever.

good thing i did , this one was broken — at Twin Motorcycles Buell Support forever.

very very big change the bike would have fallen over resting only on the top plate of the side stand.. this will bend open and the bike will fall over — at Twin Motorcycles Buell Support forever.

strap loose — at Twin Motorcycles Buell Support forever.

i know the problem.. these straps new are round.. and they need to become oval.. even for the nut to be mounted.. needs some forcing… big ass c-clip spanner works — at Twin Motorcycles Buell Support forever.

front strap in the correct position — at Twin Motorcycles Buell Support forever.

oil filter change — at Twin Motorcycles Buell Support forever.

belt check — at Twin Motorcycles Buell Support forever.

side stand mod done, using the new model pin — at Twin Motorcycles Buell Support forever.

side stand back on — at Twin Motorcycles Buell Support forever.

front spark plug in — at Twin Motorcycles Buell Support forever.

clutch cable bracket on , bended open a little for easy mounting— at Twin Motorcycles Buell Support forever.

and routing the regualtor wire as sould — at Twin Motorcycles Buell Support forever.

plug cables are older model. but still ok — at Twin Motorcycles Buell Support forever.

ziptie the tps wire to the fuel line.. — at Twin Motorcycles Buell Support forever.

air filter base plate on — at Twin Motorcycles Buell Support forever.

front wheel check// bearings are ok — at Twin Motorcycles Buell Support forever.

front forks needs some attention as they start to corrode — at Twin Motorcycles Buell Support forever.

brake fluid change front — at Twin Motorcycles Buell Support forever.

and rear.. needed to take of the reservoir.. little test ride and this one is ready — at Twin Motorcycles Buell Support forever.

on with the fuel pump as it came in , rear wheel out — at Twin Motorcycles Buell Support forever.

swingarm pivot loose , but not out — at Twin Motorcycles Buell Support forever.

fuel line loose — at Twin Motorcycles Buell Support forever.

use the center hole to fasten a lever to it to wiggle the pump out — at Twin Motorcycles Buell Support forever.

there she is — at Twin Motorcycles Buell Support forever.

the wire conenctions is the problem with this pump — at Twin Motorcycles Buell Support forever.

brand new complete unit — at Twin Motorcycles Buell Support forever.

pump back in and fuel line on — at Twin Motorcycles Buell Support forever.

swing arm pivot in again — at Twin Motorcycles Buell Support forever.

and tighten to 66 NM — at Twin Motorcycles Buell Support forever.

rear wheel back in — at Twin Motorcycles Buell Support forever.

fuel back in

and testing.. 80 psi and holding — at Twin Motorcycles Buell Support forever.

and about 50 psi while running… with not to much change in the pressure .. test ride was nice  🙂 — at Twin Motorcycles Buell Support forever.

🙂 — at Twin Motorcycles Buell Support forever.

the bike with out engine — at Twin Motorcycles Buell Support forever.

eeehhhh .. i remove this for free .. thank you — at Twin Motorcycles Buell Support forever.

ulys are so easy  🙂 supporting the rear — at Twin Motorcycles Buell Support forever.

🙂 supporting the rear — at Twin Motorcycles Buell Support forever.

rear wheel / swing arm loose — at Twin Motorcycles Buell Support forever.

engine on the lift — at Twin Motorcycles Buell Support forever.

half way there — at Twin Motorcycles Buell Support forever.

rear mount bolt first — at Twin Motorcycles Buell Support forever.

hooking up the starter motor and speedo sensor — at Twin Motorcycles Buell Support forever.

rear tie rod mounted — at Twin Motorcycles Buell Support forever.

swingarm in and mounting the axle — at Twin Motorcycles Buell Support forever.

jiffytight fittings.. replacing the o-rings.. fidely job but after a few you get the hang off it — at Twin Motorcycles Buell Support forever.

mounting first on press in the line alter

cover plate in — at Twin Motorcycles Buell Support forever.

holding the line bracket and screw on the other piece — at Twin Motorcycles Buell Support forever.

check the ware on these springs.. essecialy the oil cooler ones , you see that these have ware marks — at Twin Motorcycles Buell Support forever.

pully on for now — at Twin Motorcycles Buell Support forever.

brake fluid reservoir — at Twin Motorcycles Buell Support forever.

gearbox side , oiling ring in the main shaft — at Twin Motorcycles Buell Support forever.

shifter on — at Twin Motorcycles Buell Support forever.

and primairy drive on — at Twin Motorcycles Buell Support forever.

note the out on the mainshaft ring — at Twin Motorcycles Buell Support forever.

What did we do today: 31-5-2018, engine rebuild Buell XB12X 08, Service and check up Buell XB12STT

xb12x 08 case back from the machine shop , — atTwin Motorcycles Buell Support forever.

there was a odd ball bearing mounted, which you see the marking in al ready , desision was made to transfer back to stock

but this means the bigger hole needed to first be filled.. than new race in and hone in line for the new crank

oil jets and reed valve back in

reed valve ( case breather system ) mounted

little drop light loctite on the screws

the oil jets have stick on gaskets.. these have been reused to long

with some new gaskets back on

detend arm and spring back on

mounting tool we made

to keep the detent arm out off harms way closing the cases

cleaning the other side

and gear box needed to be pressed in

gearbox pressed in

slide the shifter forks on first

slide the shifter drum in

position the forks and place the sliding rods

cleaning and degreasing the halves

crank in

small bead off sealer on the edge

and closing the cases.. should go easy.. turn the gears and crank.. the case should drop in place

red loctite on the bolts.. and tighten the case bolts

check the gearbox of shifts ok al gears.

side play crank bearing plate in

new seal , ready greased for mounting

seal in and put the lock ring i

and spacer in.

stator mounting.. some silicone on the rubber plug will help it seal overtime

stator bolts in

mnnn some loctite left over ( counter shaft holder bolt )

clean the threads , new loctite on to hold it tight

c-clips in for the bearings

rear engine mount. and speed sensor

yining op the cams, the flats are for the oil pump

rest of the cams in

my 11 o clock apointment.. very familiar bike.. been away for some years, had some more owners not back with new owner and new motor rider, for a check up

cover of

mnnn why is everybody doing this… ? it really douse not help , and no it douse not suck vacuum to the top cover , only of you mount it bad

fuel vent ending behind the starter motor

bolt missing..

clutch cable ? routing is a little odd

some rubbing marks.. wil take care off this

and exhaust straps put on the lazy way.. looks bad.. and will hit the speed bumps

we detected leaking intake seals , so we are rotating the engine.. easy with service

clutch cable loose

losening the front strap

rear pads need replacement

rear wheel check

belt has seen better days

ok will replace it right now ..

swing arm brace removed.. and new belt on

gearbox oil in, D4 atf was already in.. upgrade clutch pack

primairy chain check.. way to loose

new pads to old ones

? hold valve open fake cable thingy ? will do this properly

engine supported and loosen the front bolt

top side connenctions loose

with the engine down.. easy to replace spark plugs

front cable douse not “click” on the coil anymore

manifold back on

exhaus strap.. front is one done

new strap on

looks better right… no bolts under the exhaust

clutch cable trough the top plate

hooking up the throttle bodie

and front end check

wheel bearings are ok

customer had a little mishap , brake lever bended but also broke

new black one mounted

do the clutch lever to .. in black

bleeehhh this has been a while since this was replaced

clean and new fluid in

rear brake also fluid change.. needed to remove the reservoir to do so ..

test ride ..  🙂 and setting the oil level.. glad to see the new owner likes the bike..

🙂 and setting the oil level.. glad to see the new owner likes the bike..

on with the engine , pinion gear on the crank

lock tool in place

26 Nm + 17 deg.. and red loctite

oil pump gasket.. please check you have the right one.. as we see very old off these gaskets , these miss a hole

oil pump in

rotors in , and cover on hold the gasket with the

3 lower bolts

tighen these with a drop of loctite.. i see these come loose ones in a while

base gaskets om

and cylinders and pistons out ( bored OS stock cylinders )

oil scraper rings on

and use the rear of the piston to push down the ring evenly to measure

check the gaps

these are ok

cleaned in hot soapy watter, check with a clean rag , it stays clean .. than some break in oil and coat the wall

pistons upsidedown

check the piston direction

clips in one side

on the connection rods.. using cylinder hold downs. to prevent the cylinders from banging up side down

rear cylinder on

and mouting the push rod covers

head on.. first the o-rings.. than locate the dowls

https://www.twinmotorcycles.nl/artikelen.asp?cid=20&aid=1238